🧭 Custom Camping Tent Process

How we work—simple, transparent, and fast. We turn your idea into a reliable product line with clear steps: brief → design → sampling → production → delivery. You’ll always know what happens next, who’s responsible, and when it’s done. Small MOQs, quick samples, factory-level QC—so you can launch on schedule and scale with confidence.

🗺️ At-a-Glance Timeline

Day 0–2: Brief & spec call → feasibility & quote

Day 3–10: CAD + prototype sample (PPS)

Day 11–14: Revisions & PPS approval

Day 15–55: Bulk production (inline QC)

Day 56–60: Final inspection, packing & shipment

Typical—not a promise. Complex models or peak seasons may extend timelines (we’ll flag early).

1) 🎯 Brief & Feasibility

What we need from you

Target users & capacity (1–2P / 3–4P / 4+)

Intended use (backpacking, family, glamping, military)

Must-have specs (waterproof mm, pole type, weight target)

Branding assets (logo, Pantone, packaging idea)

Estimated quantity & Incoterms (EXW/FOB/CIF)

What you receive

Feasibility notes + suggestions (performance vs. cost)

Indicative price ranges & MOQ windows

Initial lead-time plan and sampling slot

File types we accept: .AI/.PDF for logos; .STEP/.DXF for hardware; brand guides welcome.

2) 🧩 Co-Design & Specifications

We translate your brief into a buildable spec:

Structure: dome / tunnel / cabin / bell / pop-up

Materials: polyester/nylon/canvas; PU or silicone coatings; floor (Oxford/PE)

Hardware: 7001 Alu / fiberglass poles, YKK/SBS zippers, guy points

Details: vents, mesh, blackout lining, vestibules, footprints

Deliverables: CAD drawings, BOM, trim sheet, colorways, test plan (waterproof/UV/tear).

Goal: align performance, cost, and brand story before we stitch a single seam.

3) 🧪 Prototype Sampling (PPS)

Lead time: ~7–10 days after spec lock

What we build: a production-intent prototype using target fabrics & hardware

What we test: hydrostatic head (e.g., 2000–6000 mm), seam tape adhesion, zipper run, pole stress, setup time

You’ll get photos, dimensions, weight, and a sample report. We revise fast—usually 1–2 rounds.

4) 💬 Final Quote & Purchase Order

Once PPS is approved:

MOQ: typically 100–200 units/model (glamping/military may differ)

Pricing: confirmed per spec & volume; mixed-SKU plans available

Terms: T/T (e.g., 30% deposit, 70% before shipment); EXW/FOB/CIF

Schedule: locked production window + milestone updates

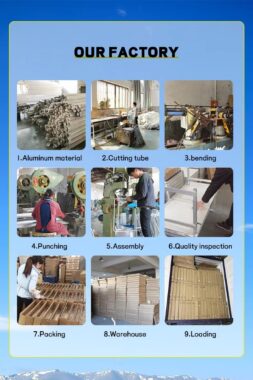

5) 🧵 Bulk Production (Inline QC)

Processes: CNC cutting → sewing → seam-taping → logo print → assembly

Inline QC: stitch density, reinforcement points, seam width, print position, pole fit

Golden Sample: PPS retained at the line as the visual & dimensional benchmark

We share progress photos/videos and catch issues early—before they reach the carton.

6) 🔎 Final QC & Compliance

AQL sampling: visual & functional checks (zippers, doors, vents, pegs/ropes count)

Performance tests: rain simulation, hydrostatic head, colorfastness, UV exposure

Documentation: QC report with measurements & images; CO/packing list/MSDS if needed

3rd party inspection: SGS/BV/Intertek on request (we coordinate)

7) 📦 Packaging, Labels & Logistics

Retail-ready options: branded carry bag, hangtag, barcode, multilingual manual

Cartons: optimized CBM, clear SKU labels, palletized for export safety

Shipping: EXW/FOB/CIF; consolidation available with other items (chairs/mats/hammocks)

For mixed loads and bulk terms, see Camping Tent Wholesale on your site.

8) 🤝 After-Sales, Reorders & Iterations

We keep your BOM, color codes, and patterns on file to make reorders effortless.

Spare parts & fabric kits available

Continuous improvement (cost/weight tweaks, seasonal colors)

Launch support (spec sheets, product photos on request)

Long-term, we become your quiet R&D arm—so your line stays fresh without heavy overhead.

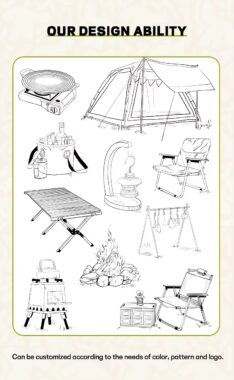

🛠️ What We Customize (Quick Recap)

Fabric & Finish: polyester/nylon/canvas; PU/silicone coatings; UV/FR options

Capacity & Layout: 1–2P, 3–4P, 4+; vestibules, rooms, porches

Frame & Hardware: aluminum/fiberglass poles; premium zippers; guy systems

Branding: screen/transfer/embroidery; Pantone-matched trims; retail packs

Add-ons: blackout inner, extra vents, footprints, canopies, windows

🧾 FAQs (Process-Focused)

Q1: Can you start with a small order?

Yes. We support small MOQs for new launches. Your spec stays the same; only volume changes.

Q2: How many sample rounds are typical?

Usually 1–2. We aim to lock specs early with clear design notes, saving time and cost.

Q3: Can you match my brand colors exactly?

Yes—Pantone matching across flysheet, webbing, stitching, and bags for a cohesive line.

Q4: Do you handle third-party inspections?

Absolutely. We coordinate SGS/BV/Intertek and prepare samples, space, and paperwork.

📣 Call to Action

Ready to start? Share your brief, logo files, and target specs—we’ll map a production plan within 48 hours and book your sampling slot.

Prefer to browse first? Your homepage targeting Camping Tent Manufacturers and your Camping Tent Wholesale page already frame the big picture; this process page is how we deliver it—step by step.